Choosing suitable and reliable roofing materials for industrial buildings is much harder than residential and commercial roofing systems. Since you should put a value on all the merchandise being manufactured inside your buildings, getting a roof that provides the best protection is essential.

To cut off on their expenses, some businessmen tend to go for inferior roofing for industrial buildings. However, it just puts more money down the drain due to damage repairs. In this article, we will help you find out the best roofing material that you can use for your industrial buildings. Let’s go!

What is an industrial roof?

An industrial roof is a type of roofing system used on large commercial and industrial buildings. It typically consists of a structural deck, insulation, vapor retarder, and a waterproof membrane. Industrial roofs are designed to withstand extreme temperatures and weather conditions, such as high winds and heavy snowfall. They also provide protection from fire, water, and chemical exposure.

What are industrial roofs made of?

Industrial roofs are typically made of metal, such as steel or aluminum. They can also be made of concrete, asphalt, rubber membrane, bitumen felt, and other materials. The type of material used depends on the needs of the building and the climate in which it is located.

Best Types of Roofing for Industrial Buildings

Thermoplastic Polyolefin Roofing

Thermoplastic Polyolefin (TPO) roofing is made from a single-ply membrane roofing structure and it usually covers the roof’s surface. Even though this roofing material has “plastic” on its name, it is usually made with different types of rubbers, ethylene, propylene, and fiberglass.

You can purchase this roofing material in different sizes and colors like green, tan, and red. For starters, thermoplastic polyolefin roofing is commonly installed on flat roofs, so that should always be one of your top considerations before choosing this type of roofing.

[Related: 6 Flat Roof Maintenance Tips To Avoid Costly Damages]

TPO is, by far, the most affordable roofing material that you can find in the market, but that doesn’t mean it is inferior in terms of quality. This roofing system is also resistant to fat and oils, making it a great choice for industrial buildings that manufacture food items.

Other benefits of using this roofing system include:

- Durable

- UV resistant

- Fire resistant

- Chemical resistant

- Puncture resistant

- Wind resistant

- With 20 years of lifespan

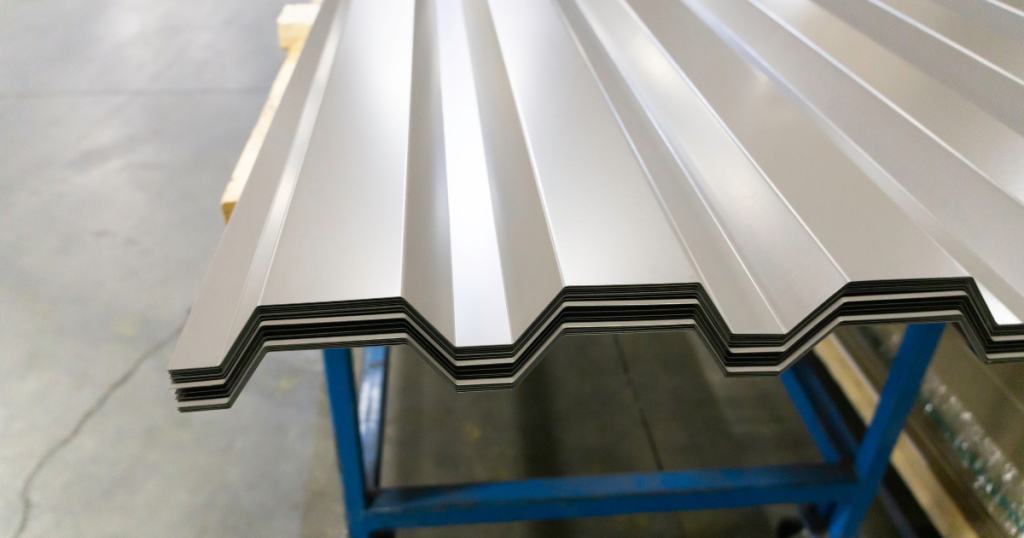

Metal Roofing

We often see industrial buildings with metal roofing since these establishments require a highly durable roofing system to protect all the merchandise being manufactured inside the building. Metal roofing is usually installed on pitched roofs.

There are a lot of options that you can choose from for this type of roofing like copper, aluminum, corrugated galvanized steel, tin, stainless steel, and stone-coated steel. Each of these materials varies in terms of resistance and looks, and it all depends on you, the client, on what type of roofing material would suit your industrial building.

[Related: 5 Types Of Metal Roofing: Costs, Benefits, And Drawbacks]

Metal roofing is known to be prone to rust and dents, but the emerging technology in the flooring industry made metal roofing tougher than ever. Now, most metal roofs can last up to 40 years without a sign of rusting and they are now very resistant to denting.

Other benefits of using this roofing system include:

- Versatile material

- Wind resistant

- Fire resistant

- Wind resistant

- Works well even during the snow season

Thermoset Roof Membrane

Another reliable industrial roofing system is the thermoset roof membrane or also called the EPDM rubber roofing, EPDM roofing membrane, rubber roofing, rubber membrane roofing, and rolled rubber roofing. Just like TPO, it is also a single-ply membrane type of roofing material. It comes in a single-ply membrane and it is usually installed on buildings with low slopes.

EPDM roofs are made from a mixture of sawdust, slate dust, and recycled tires. Aside from being affordable and lightweight, it is also very easy to install. If you have a bit of experience, you can actually install this roofing system on your roof deck since it does not need any reinforcements.

Other benefits of using this roofing system include:

- Fire resistant

- UV resistant

- Cold resistant

- Acid resistant

- Alcohol resistant

- Solvent resistant

Modified Bitumen

A modified bitumen roof can sometimes be regarded as built-up roofing because they have the same application procedures. This roof system is usually installed in buildings with little to no slope. The difference between a modified bitumen and a built-up roof is that the former is applied solid, while the latter is liquid.

A professional roofing company installs modified bitumen roofs by rolling the three-foot rolls and heating them with a torch to allow the material to spread out into the surface of the roof. Extra protection is usually added to make the roof resistant to UV damage.

If you have an industrial building wherein high foot traffic is expected on the roof, which means that a lot of people would be walking on your roof deck, this material should be one of your top choices.

Other benefits of using this roofing system include:

- Can resist extreme weather conditions

- Durable

- High resistance to cracking during winter

- Minimal maintenance

- Durable even with heavy foot traffic

Need More Help in Choosing the Right Roof for You?

In the roofing industry, you need to have a reliable contractor to help you choose the right roofing materials for your industrial property. Easy Roof Solutions provide 24/7 services in installation, repairs, maintenance, and more!

We can also help you find out the most suitable commercial roofing materials and residential roof systems depending on your needs. Just give us a call and we’re always ready to help!

Ken Byler

Founder of Easy Roof Solutions, LLC. He started in the construction industry at the age of 14 and has been involved in it for over 25 years. His wide experience in commercial roofing speaks for itself.

Outside his roofing work, Ken enjoys being in the great outdoors, traveling to new places, and bonding with his wife and children.