Not everyone knows that water can create irreparable damage to many types of roofing material, and we don’t want that to happen to your roof! As business owners, keeping the entire structure of your building less susceptible to damage lies under the condition of your roof.

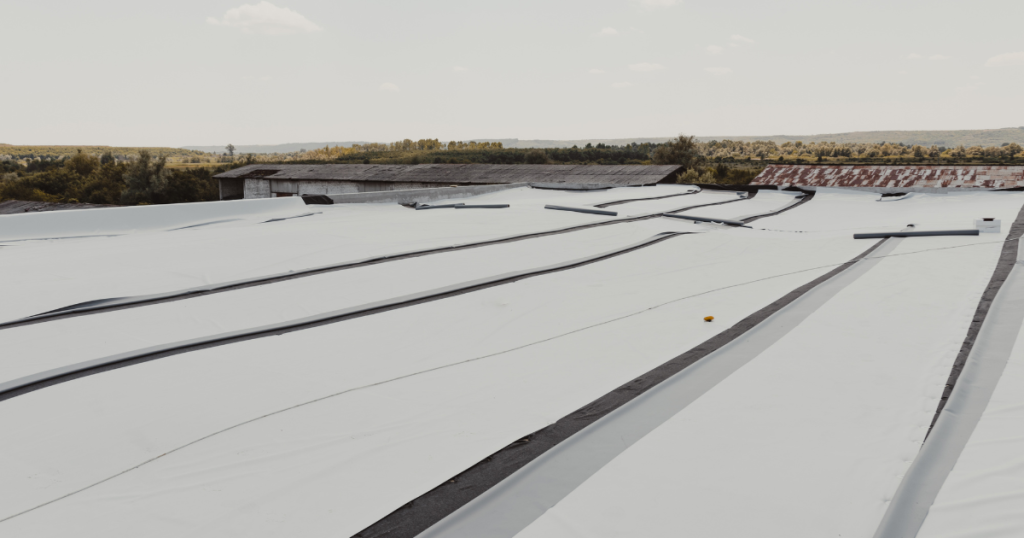

One way to protect your roof is to apply commercial roof waterproofing materials. These materials can help lengthen the lifespan of your roof and prevent any possible instances of roof replacement or repairs once it’s installed properly.

A waterproofing roof membrane can be applied to common roof structures like metal roof, flat roof, etc. To learn more about the different types of waterproofing solutions for your commercial building, read on!

Bituminous Waterproofing Membrane

This waterproofing material is made with modified bitumen, and other materials like polyester felt or fiberglass. It comes in a liquid membrane or a bitumen-based roll membrane. A bituminous waterproofing membrane is commonly applied on flat roofs, walls, and foundations.

Application Process:

Before the waterproofing process starts, it is important to clean off all the debris on the roof using a broom or an air blower.

Bituminous waterproofing membrane involves the use of a blow torch to heat up the membrane until it becomes soft and pliable. After that, the heated material is pressed onto the roofing structure.

The waterproof membrane can also be applied using a cold method with the help of a special adhesive.

Benefits:

- Can be applied on any surface

- Flexible material

- Can be applied on interior and exterior corners of walls, chimney edges, parapet returns, etc.

- Long lifespan

- Resistant to UV rays

- Can be easily repaired

Self-Adhesive Membrane

Did you know that a waterproofing roof membrane has also been innovated into a self-adhesive membrane? An easily peelable waterproof membrane made from polyester felt and fiberglass is now available for your waterproofing of metal roofs, concrete surfaces, and sloping concrete roofing.

Application process:

First off, the surface must be cleaned and free from any dirt and debris since it could affect the adhesion of the roof waterproofing material. Cracks and holes should also be checked and repaired before the process starts.

Next, a liquid primer will be applied to make sure that the optimum adherence of the self-adhesive membrane. The membrane has to be cut into appropriate sizes, then peel off the membrane and press it firmly.

Bubbles and wrinkles should be smoothed out. Lastly, excess material should be trimmed before applying a flashing grade sealant.

Benefits:

- Easy to install since it requires less labor

- Flexible and long-lasting

- Can withstand harsh weather conditions

- Easy to apply on edges of chimneys and parapet walls

- Can be installed in areas with freezing temperature

- No heat and flame are needed for installation

- Cost-effective than traditional waterproofing application methods

SBS (Styrene Butadiene Styrene) Modified Waterproofing Membrane

This roof waterproofing membrane consists of a blend of polymers made from styrene butadiene styrene (SBS), asphalt, fiberglass, and some fillers. One layer of this roof waterproof material is coated with a polyethylene film and the other layer can be coated with some mineral stones, silica sand, or aluminum foil.

Application Process:

Just like the first two roof waterproofing membranes, the surface of the roof has to be cleaned off and free from any contaminants. Priming using a liquid primer should also be applied.

Next, the mineral stone coated later should be heated up on the joint and the minerals should be buried using a trowel.

Benefits:

- Applicable to various kinds of surfaces even at cold temperatures

- Can be applied to chimneys and parapet returns

- Highly flexible and durable

- Resistant to UV rays

FAQs About Commercial Waterproofing Materials

How do I waterproof my roof?

While it is possible to waterproof your roof yourself, it’s not easy. If you’re willing to learn how, here are the steps:

1. Clean off all loose dirt, leaves, and debris with a broom or leaf blower.

2. Apply a penetrating sealant with a paintbrush or roller applicator. You have to make sure that you cover any cracks or holes in the surface of your roof as well as any seams between shingles or tiles.

3. Let the sealant or waterproofing materials dry for 24 hours before applying another coat, again making sure to cover all seams and cracks/holes on the surface of your roof.

[Related: What Is Waterproofing Roof Membrane? Uses, Types, Applications]

Which waterproofing is best for an old roof?

The best waterproofing method for an old roof will depend on the condition of the existing roof surface and the type of roofing material used for the establishment. It is recommended that you consult with a professional roofer to determine the best course of action

Does roof coating stop leaks?

This all depends on the current condition of your roofing system. If the roof is in good condition and it never had any major water leak issues, applying a waterproof coating can prevent further leaks. However, if the roof already has lots of leaking, necessary repairs should be done before applying a roof waterproofing membrane.

[Related: 5 Things To Know When Waterproofing Commercial Building Structures]

Have Your Roof Waterproofing Done by a Professional

Now that you’ve got the information you need about commercial roof waterproofing materials, it should be much easier for you to get everything squared away on your next commercial construction project.

Hire a credible roofing contractor like Easy Roof Solutions to make sure that leaks, mold, and mildew would not cause any damage to your commercial roof. Get a free quote today!

Ken Byler

Founder of Easy Roof Solutions, LLC. He started in the construction industry at the age of 14 and has been involved in it for over 25 years. His wide experience in commercial roofing speaks for itself.

Outside his roofing work, Ken enjoys being in the great outdoors, traveling to new places, and bonding with his wife and children.